SOUND POWER MEASUREMENT

Our services

- Determination of the sound power level or the emission sound pressure level of plants, machines, devices and assemblies

- Sound power measurement according to DIN EN ISO 9614 1-3 by means of sound intensity measurement

- Sound power measurement according to DIN EN ISO 3744 / 3746 by means of sound pressure measurement

- Measurement according to the Outdoor Noise Directive (2000/14/EC)

- Measurement of emission variables on site

- Determination of sound power level for research purposes

- Individual determination of the sound power levels for your plant

- Advice on the technically correct assessment of your products

- Determination of sound emissions for already manufactured products as well as for products in the development phase by means of comparative measurements

What is the purpose of sound power measurement

- A quiet machine is a sign of high quality

- By means of the sound power measurement it can be determined whether sound insulation is necessary

- The Machinery Directive 2006/42/EC requires the specification of the airborne sound emission of the machine at the workplace. If the sound pressure level of 80 dB(A) is exceeded, the specification of the sound power is required.

- Early detection of damage through noise and vibration measurements

Methods for sound power determination

The sound power can be determined in two ways. The distinction is made between sound power determination by means of sound pressure measurement and sound power determination by means of sound intensity measurement.

Sound pressure measurement

Sound pressure measurement is characterized by the fact that only the local sound pressure level and all of its disturbance variables is recorded at a measurement location. Thus, we know how loud it is at this local point, but not from which direction the sound is coming. This method is therefore well suited in a quiet measurement environment with little background noise.

Sound intesity measurement

In a measurement environment with potential noise interference, a sound intensity measurement should be performed to determine the sound power. This is particularly useful for stationary systems that are operating in a production hall. In contrast to the sound pressure measurement, the sound intensity is a vectorial quantity, so that the direction of the sound can be determined.

Ambient noise can thus be better detected and excluded from the results. The sound power can therefore usually be determined more accurately by means of sound intensity measurements.

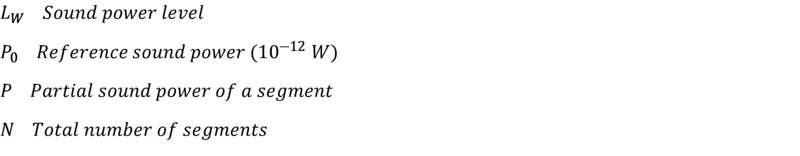

Execution of a sound power measurement

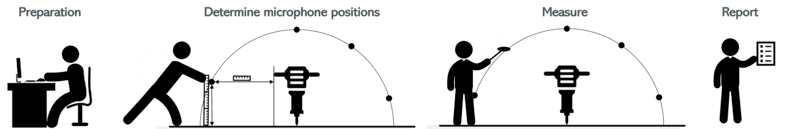

The sound power is usually determined according to standardized measurement methods. The following pictogram schematically illustrates the general procedure of a sound power measurement.

- Preparation

- Determine microphone positions

- Measurement

- Logging

Step 1. Preparation:

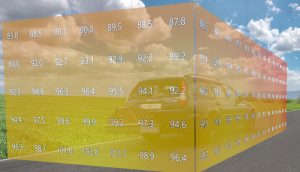

The first step is the selection of the standard according to which the measurement is to be performed. The two series of standards DIN EN ISO 3740 – 3746 and DIN EN ISO 9614 1 – 3 are mainly used for this purpose. The main difference between these two standards is that sound pressure is measured in the 374x series, whereas sound intensity is measured in the 9614 series. However, both series of standards have in common that sound pressure or sound intensity measurements have to be performed at numerous, spatially precisely defined positions. The measurement positions are usually located on an enveloping surface surrounding the measurement object, which can be cuboid, cylindrical or spherical shaped, depending on the underlying standard and sound source. The dimensions of the enveloping surface and the measured sound quantities (Pa or W/m²) are finally used to determine the total sound power level.

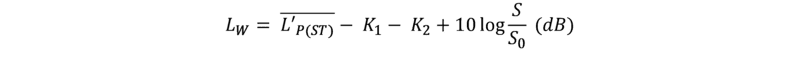

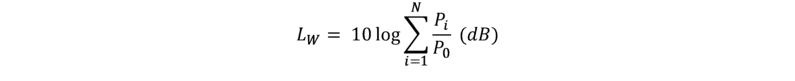

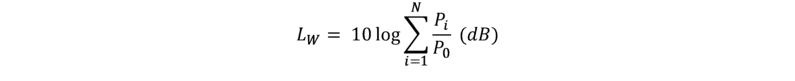

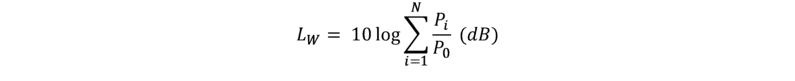

Calculation LW for a sound pressure measurement (according to DIN EN ISO 3744):

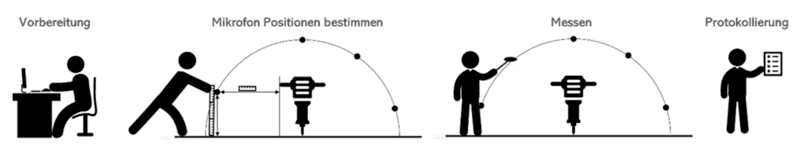

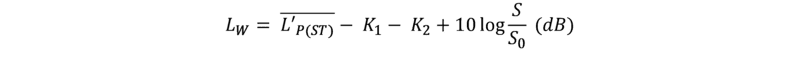

Calculation LW for a sound intensity measurement (according to DIN EN ISO 9614-1):

Step 2. Determine microphone positions:

In practice, however, measuring the standard-compliant measuring positions is very time-consuming and in some cases it is even left to the eye of the measuring engineer. Often, self-made constructions or adhesive tape markings on the floor are used to help. With the sound intensity module of our augmented reality software, however, this is no longer necessary. After entering the dimensions of the measurement object, the AR glasses automatically calculate the enveloping surface and the measurement positions and display them with spatial accuracy. The measurement setup can be seen virtually in space and it remains stationary in place. Thus, the measurement engineer can walk around it and conveniently perform the measurement at all virtual positions.

Step 3. Measurement:

During the measurement, certain criteria must be observed. A selection of these criteria is listed here:

- The levels measured at the respective measuring locations must not vary too much

- The background noise must meet certain criteria (e.g. 10dB quieter than the level to be measured)

- The measuring equipment must meet certain quality requirements

Step 4. Logging:

Finally, the logging and the interpretation of the measurement results are carried out. The exact information that must be included in a complete report can be found in the standards mentioned.

SOUND POWER MEASUREMENT

Our services

- Determination of the sound power level or the emission sound pressure level of plants, machines, devices and assemblies

- Sound power measurement according to DIN EN ISO 9614 1-3 by means of sound intensity measurement

- Sound power measurement according to DIN EN ISO 3744 / 3746 by means of sound pressure measurement

- Measurement according to the Outdoor Noise Directive (2000/14/EC)

- Measurement of emission variables on site

- Determination of sound power level for research purposes

- Individual determination of the sound power levels for your plant

- Advice on the technically correct assessment of your products

- Determination of sound emissions for already manufactured products as well as for products in the development phase by means of comparative measurements

What is the purpose of sound power measurement

- A quiet machine is a sign of high quality

- By means of the sound power measurement it can be determined whether sound insulation is necessary

- The Machinery Directive 2006/42/EC requires the specification of the airborne sound emission of the machine at the workplace. If the sound pressure level of 80 dB(A) is exceeded, the specification of the sound power is required.

- Early detection of damage through noise and vibration measurements

Methods for sound power determination

The sound power can be determined in two ways. The distinction is made between sound power determination by means of sound pressure measurement and sound power determination by means of sound intensity measurement.

Sound pressure measurement

Sound pressure measurement is characterized by the fact that only the local sound pressure level and all of its disturbance variables is recorded at a measurement location. Thus, we know how loud it is at this local point, but not from which direction the sound is coming. This method is therefore well suited in a quiet measurement environment with little background noise.

Sound intesity measurement

In a measurement environment with potential noise interference, a sound intensity measurement should be performed to determine the sound power. This is particularly useful for stationary systems that are operating in a production hall. In contrast to the sound pressure measurement, the sound intensity is a vectorial quantity, so that the direction of the sound can be determined.

Ambient noise can thus be better detected and excluded from the results. The sound power can therefore usually be determined more accurately by means of sound intensity measurements.

Execution of a sound power measurement

The sound power is usually determined according to standardized measurement methods. The following pictogram schematically illustrates the general procedure of a sound power measurement.

- Preparation

- Determine microphone positions

- Measurement

- Logging

Step 1. Preparation:

The first step is the selection of the standard according to which the measurement is to be performed. The two series of standards DIN EN ISO 3740 – 3746 and DIN EN ISO 9614 1 – 3 are mainly used for this purpose. The main difference between these two standards is that sound pressure is measured in the 374x series, whereas sound intensity is measured in the 9614 series. However, both series of standards have in common that sound pressure or sound intensity measurements have to be performed at numerous, spatially precisely defined positions. The measurement positions are usually located on an enveloping surface surrounding the measurement object, which can be cuboid, cylindrical or spherical shaped, depending on the underlying standard and sound source. The dimensions of the enveloping surface and the measured sound quantities (Pa or W/m²) are finally used to determine the total sound power level.

Calculation LW for a sound pressure measurement (according to DIN EN ISO 3744):

![]()

Calculation LW for a sound intensity measurement (according to DIN EN ISO 9614-1):

![]()

Step 2. Determine microphone positions:

In practice, however, measuring the standard-compliant measuring positions is very time-consuming and in some cases it is even left to the eye of the measuring engineer. Often, self-made constructions or adhesive tape markings on the floor are used to help. With the sound intensity module of our augmented reality software, however, this is no longer necessary. After entering the dimensions of the measurement object, the AR glasses automatically calculate the enveloping surface and the measurement positions and display them with spatial accuracy. The measurement setup can be seen virtually in space and it remains stationary in place. Thus, the measurement engineer can walk around it and conveniently perform the measurement at all virtual positions.

Step 3. Measurement:

During the measurement, certain criteria must be observed. A selection of these criteria is listed here:

- The levels measured at the respective measuring locations must not vary too much

- The background noise must meet certain criteria (e.g. 10dB quieter than the level to be measured)

- The measuring equipment must meet certain quality requirements

Step 4. Logging:

Finally, the logging and the interpretation of the measurement results are carried out. The exact information that must be included in a complete report can be found in the standards mentioned.

Sound power measurement

Our services

- Determination of the sound power level or the emission sound pressure level of plants, machines, devices and assemblies

- Sound power measurement according to DIN EN ISO 9614 1-3 by means of sound intensity measurement

- Sound power measurement according to DIN EN ISO 3744 / 3746 by means of sound pressure measurement

- Measurement according to the Outdoor Noise Directive (2000/14/EC)

- Measurement of emission variables on site

- Determination of sound power level for research purposes

- Individual determination of the sound power levels for your plant

- Advice on the technically correct assessment of your products

- Determination of sound emissions for already manufactured products as well as for products in the development phase by means of comparative measurements

What is the purpose of sound power measurement

- A quiet machine is a sign of high quality

- By means of the sound power measurement it can be determined whether sound insulation is necessary

- The Machinery Directive 2006/42/EC requires the specification of the airborne sound emission of the machine at the workplace. If the sound pressure level of 80 dB(A) is exceeded, the specification of the sound power is required.

- Early detection of damage through noise and vibration measurements

Methods for sound power determination

The sound power can be determined in two ways. The distinction is made between sound power determination by means of sound pressure measurement and sound power determination by means of sound intensity measurement.

Sound pressure measurement

Sound pressure measurement is characterized by the fact that only the local sound pressure level and all of its disturbance variables is recorded at a measurement location. Thus, we know how loud it is at this local point, but not from which direction the sound is coming. This method is therefore well suited in a quiet measurement environment with little background noise.

Sound intesity measurement

In a measurement environment with potential noise interference, a sound intensity measurement should be performed to determine the sound power. This is particularly useful for stationary systems that are operating in a production hall. In contrast to the sound pressure measurement, the sound intensity is a vectorial quantity, so that the direction of the sound can be determined.

Ambient noise can thus be better detected and excluded from the results. The sound power can therefore usually be determined more accurately by means of sound intensity measurements.

Execution of a sound power measurement

The sound power is usually determined according to standardized measurement methods. The following pictogram schematically illustrates the general procedure of a sound power measurement.

![]()

- Preparation

- Determine microphone positions

- Measurement

- Logging

Step 1. Preparation:

The first step is the selection of the standard according to which the measurement is to be performed. The two series of standards DIN EN ISO 3740 – 3746 and DIN EN ISO 9614 1 – 3 are mainly used for this purpose. The main difference between these two standards is that sound pressure is measured in the 374x series, whereas sound intensity is measured in the 9614 series. However, both series of standards have in common that sound pressure or sound intensity measurements have to be performed at numerous, spatially precisely defined positions. The measurement positions are usually located on an enveloping surface surrounding the measurement object, which can be cuboid, cylindrical or spherical shaped, depending on the underlying standard and sound source. The dimensions of the enveloping surface and the measured sound quantities (Pa or W/m²) are finally used to determine the total sound power level.

Calculation LW for a sound pressure measurement (according to DIN EN ISO 3744):

![]()

Calculation LW for a sound intensity measurement (according to DIN EN ISO 9614-1):

![]()

Step 2. Determine microphone positions:

In practice, however, measuring the standard-compliant measuring positions is very time-consuming and in some cases it is even left to the eye of the measuring engineer. Often, self-made constructions or adhesive tape markings on the floor are used to help. With the sound intensity module of our augmented reality software, however, this is no longer necessary. After entering the dimensions of the measurement object, the AR glasses automatically calculate the enveloping surface and the measurement positions and display them with spatial accuracy. The measurement setup can be seen virtually in space and it remains stationary in place. Thus, the measurement engineer can walk around it and conveniently perform the measurement at all virtual positions.

Step 3. Measurement:

During the measurement, certain criteria must be observed. A selection of these criteria is listed here:

- The levels measured at the respective measuring locations must not vary too much

- The background noise must meet certain criteria (e.g. 10dB quieter than the level to be measured)

- The measuring equipment must meet certain quality requirements

Step 4. Logging:

Finally, the logging and the interpretation of the measurement results are carried out. The exact information that must be included in a complete report can be found in the standards mentioned.