Imagine putting on a pair of glasses and seeing all the information you need to measure sound in front of you in a matter of seconds.

Measurement procedure

1. Adjust reference cuboid

The operator puts on the AR glasses, starts the HoloMetrix app and conveniently enters the dimensions of the measurement object in the menu window that appears in the room. The augmented reality glasses (HoloLens 2) then automatically create a virtual reference cuboid, which is placed over the measurement object using drag and drop.

2. Create enveloping surface

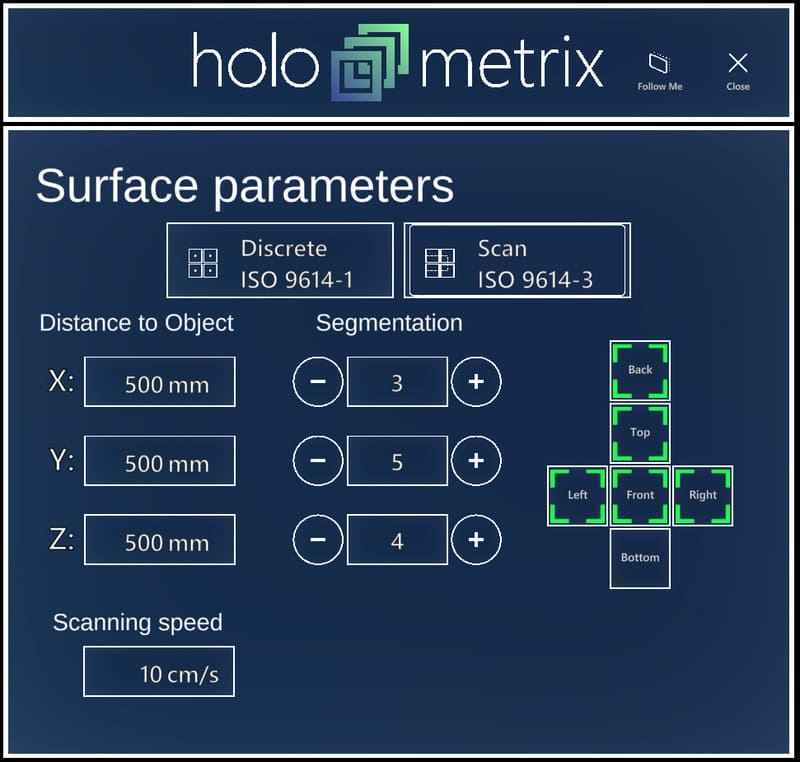

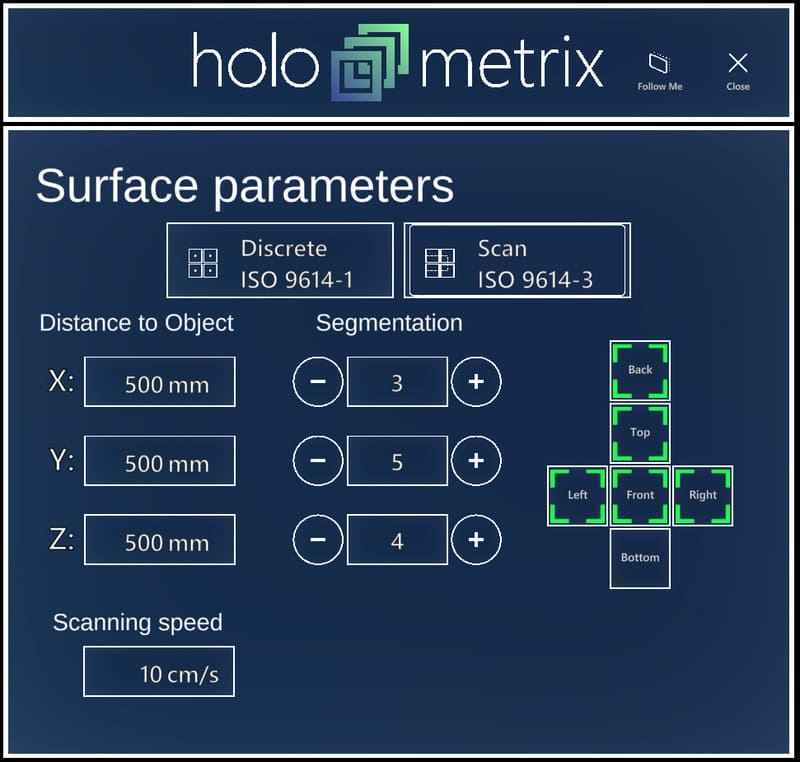

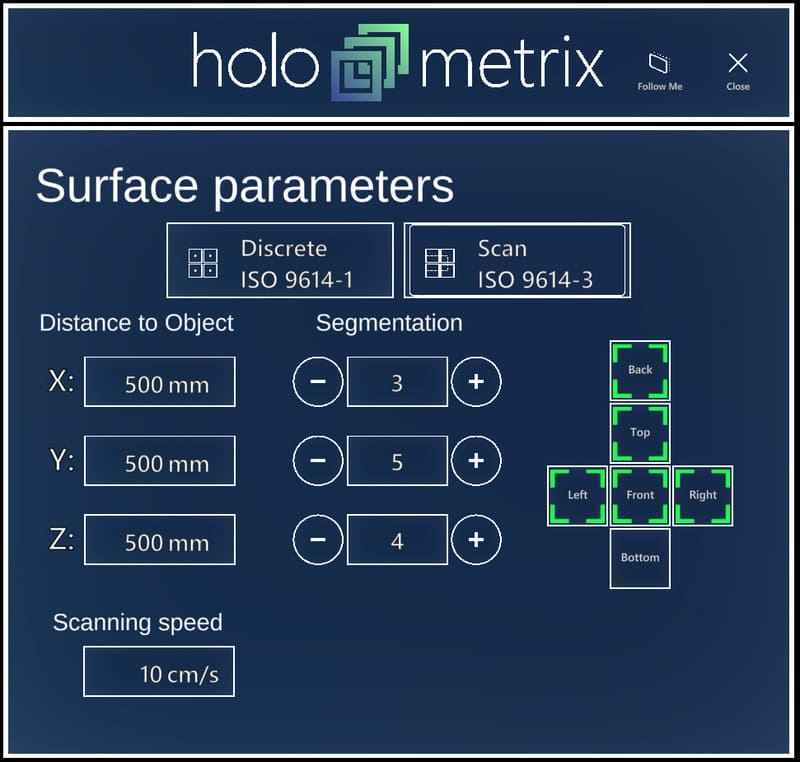

A menu window appears in which the number of segments as well as the distance to the measurement object can be conveniently entered. In addition, the measurement surfaces on which measurements are not to be taken can be hidden. Visual feedback in the form of a traffic light system lets you know at any time whether the settings are in conformity with the standard.

You can choose between a measurement with discrete (DIN EN ISO 9614 – 1) measuring points and a measurement using a scan path (DIN EN ISO 9614 – 3).

By clicking on the „Setup Surface“ button, the measuring grid is automatically calculated and displayed.

3. Perform measurement

In the case of a discrete measurement, the standard-compliant measurement positions are displayed by clicking on the „Start Measuring“ button. The operator now simply aligns the measuring probe to the virtual measuring points and starts the measurement in the measuring software* on the PC.

*You can request a list of supported software here.

Similarly, the scan path is generated automatically for a measurement using the scanning method. First, the measuring probe is aligned at the beginning of the path. After clicking on „Start“, a ball moves along the path at a previously defined speed. Simply following the virtual ball with your real probe ensures that you scan in compliance with the standards. This avoids costly repeated measurements.

4. Result presentation

The measured values can then be entered into the respective segments via a menu window. A sound field map is automatically created from these values. On the one hand, this visualization significantly facilitates the interpretation and, on the other hand, the detection of acoustic problem zones. Subsequently, measures can be taken to reduce the acoustic emissions of the measurement object, if this is necessary.

Your advantages

No time-consuming measuring

- The standard measuring positions are automatically calculated and displayed by the augmented reality glasses

More accurate measurement results

- No coordination of different hardware necessary

- Obstacles like pipelines which are in the way can be considered

Time and cost savings

- No capital-intensive auxiliary constructions are required

- By eliminating long preparation and post-processing times, the measuring time is reduced by up to 80 %

Flexibility and mobility

- The measurement is feasible for objects of any size

- No binding to a specific geometry of the measuring grid

- The measurement can be performed both indoors and outdoors

Easy interpretation of results

- The measurement results are automatically evaluated and can be displayed in the form of a sound field map immediately after the measurement over the measured object

Request a free product presentation and convince yourself!

HoloLens 2

Comprehensive

- large field of view

- best resolution

- The objects do not move with the field of view, but remain stationary

Comfortable

- The augmented reality glasses rest on your forehead and are therefore comfortable to wear

- if you are not carrying out a measurement, the display can simply be folded up

Intuitive

- Intuitive operation through automatic tracking of your hands

- Interact with virtual objects, like with physical objects

- Voice recognition

Independent

- The HoloLens 2 can be compared to a computer. It is therefore not bound to additional hardware and can be used independently

- Unlimited freedom of movement through wireless operation

Engineering Services

We offer a variety of acoustic measurements by using our own equipment.

HoloMetrix News

Don’t miss out on news about innovative products, exclusive offers and useful services.

The company excelled in the “Excellence in Business to Business” competition class in the “Machines & Engineering” category with the “HoloMetrix –Sound HUB”, a positioning aid that significantly simplifies acoustic measurements using augmented reality. In AR glasses, a virtual experimental set-up is presented three-dimensionally in the real environment. This approach eliminates the time-consuming and tedious manual determination of the measuring positions.

This is a significant step forward from the usual procedures offering an impressive demonstration of what measurement will look like in the future,” according to the jury’s statement.

Read the full article here.

Imagine putting on a pair of glasses and seeing all the information you need to measure technical acoustics in front of you in a matter of seconds.

Measurement procedure

1. Adjust reference cuboid

The operator puts on the AR glasses, starts the HoloMetrix app and conveniently enters the dimensions of the measurement object in the menu window that appears in the room. The augmented reality glasses (HoloLens 2) then automatically create a virtual reference cuboid, which is placed over the measurement object using drag and drop

2. Create enveloping surface

A menu window appears in which the number of segments as well as the distance to the measurement object can be conveniently entered. In addition, the measurement surfaces on which measurements are not to be taken can be hidden. Visual feedback in the form of a traffic light system lets you know at any time whether the settings are in conformity with the standard.

By clicking on the „Setup Surface“ button, the measuring grid is automatically calculated and displayed.

3. Perform measurement

In the case of a discrete measurement, the standard-compliant measurement positions are displayed by clicking on the „Start Measuring“ button. The operator now simply aligns the measuring probe to the virtual measuring points and starts the measurement in the measuring software* on the PC.

*You can request a list of supported software here.

Similarly, the scan path is generated automatically for a measurement using the scanning method. First, the measuring probe is aligned at the beginning of the path. After clicking on „Start“, a ball moves along the path at a previously defined speed.

Simply following the virtual ball with your real probe ensures that you scan in compliance with the standards. This avoids costly repeated measurements.

4. Result presentation

The measured values can then be entered into the respective segments via a menu window. A sound field map is automatically created from these values. On the one hand, this visualization significantly facilitates the interpretation and, on the other hand, the detection of acoustic problem zones. Subsequently,

measures can be taken to reduce the acoustic emissions of the measurement object, if this is necessary.

Your advantages

Time and cost savings

- No capital-intensive auxiliary constructions are required

- By eliminating long preparation and post-processing times, the measuring time is reduced by up to 80 %

Flexibility and mobility

- The measurement is feasible for objects of any size

- No binding to a specific geometry of the measuring grid

- The measurement can be performed both indoors and outdoors

Easy result interpretation

- The measurement results are automatically evaluated and can be displayed in the form of a sound field map immediately after the measurement over the measured object

No time-consuming measuring

- The standard measuring positions are automatically calculated and displayed by the augmented reality glasses

Accurate measurement results

- No coordination of different hardware necessary

- Obstacles like pipelines which are in the way can be considered

Request a free product presentation and convince yourself!

HoloLens 2

Comprehensive

- large field of view

- best resolution

- The objects do not move with the field of view, but remain stationary

Comfortable

- The augmented reality glasses rest on your forehead and are therefore comfortable to wear

- if you are not carrying out a measurement, the display can simply be folded up

Intuitive

- Intuitive operation through automatic tracking of your hands

- Interact with virtual objects, like with physical objects

- Voice recognition

Independent

- The HoloLens 2 can be compared to a computer. It is therefore not bound to additional hardware and can be used independently

- Unlimited freedom of movement through wireless operation

Engineering Services

We offer a variety of acoustic measurements by using our own equipment.

HoloMetrix News

Don’t miss out on news about innovative products, exclusive offers and useful services.

Honoured with the German Innovation Award in “Gold”

The company excelled in the “Excellence in Business to Business” competition class in the “Machines & Engineering” category with the “HoloMetrix –Sound HUB”, a positioning aid that significantly simplifies acoustic measurements using augmented reality. In AR glasses, a virtual experimental set-up is presented three-dimensionally in the real environment. This approach eliminates the time-consuming and tedious manual determination of the measuring positions.

This is a significant step forward from the usual procedures offering an impressive demonstration of what measurement will look like in the future,” according to the jury’s statement.

Read the full article here.

Mit dem SI Local Modul sehen Sie alle Informationen, die Sie für eine technische Akustikmessung benötigen, in Sekundenschnelle vor sich.

Measurement procedure

1.

Adjust reference cuboid

The operator puts on the AR glasses, starts the HoloMetrix app and conveniently enters the dimensions of the measurement object in the menu window that appears in the room. The augmented reality glasses (HoloLens 2) then automatically create a virtual reference cuboid, which is placed over the measurement object using drag and drop.

2.

Create enveloping surface

A menu window appears in which the number of segments as well as the distance to the measurement object can be conveniently entered. In addition, the measurement surfaces on which measurements are not to be taken can be hidden. Visual feedback in the form of a traffic light system lets you know at any time whether the settings are in conformity with the standard.

You can choose between a measurement with discrete (DIN EN ISO 9614 – 1) measuring points and a measurement using a scan path (DIN EN ISO 9614 – 3).

By clicking on the „Setup Surface“ button, the measuring grid is automatically calculated and displayed.

3.

Perform measurement

In the case of a discrete measurement, the standard-compliant measurement positions are displayed by clicking on the „Start Measuring“ button. The operator now simply aligns the measuring probe to the virtual measuring points and starts the measurement in the measuring software* on the PC.

*You can request a list of supported software here.

Similarly, the scan path is generated automatically for a measurement using the scanning method. First, the measuring probe is aligned at the beginning of the path. After clicking on „Start“, a ball moves along the path at a previously defined speed. Simply following the virtual ball with your real probe ensures that you scan in compliance with the standards. This avoids costly repeated measurements.

4.

Result presentation

The measured values can then be entered into the respective segments via a menu window. A sound field map is automatically created from these values. On the one hand, this visualization significantly facilitates the interpretation and, on the other hand, the detection of acoustic problem zones. Subsequently, measures can be taken to reduce the acoustic emissions of the measurement object, if this is necessary.

Request a free product presentation and convince yourself!

Your advantages

More accurate measurement results

- The standard measuring positions are automatically calculated and displayed by the augmented reality glasses.

More accurate measurement results

- The AR glasses function independently. No external device (e.g. computer or smartphone) is required.

- Obstacles in the way, such as pipelines, can be taken into account.

Time and cost savings

- The elimination of long preparation and post-processing times reduces the measurement time by up to 80%.

- The time reduction leads to cost savings of € 37.500 / year on average

Flexibility and mobility

- The measurement is feasible for objects of any size.

- No binding to a specific geometry of the measuring grid.

- The measurement can be performed both indoors and outdoors.

Easy interpretation of results

- The measurement results are automatically evaluated and can be displayed in the form of a sound field map over the measured object immediately after the measurement.

HoloLens 2

Comprehensive

- large field of view

- best resolution

- The objects do not move with the field of view, but remain stationary

Comfortable

- The augmented reality glasses rest on your forehead and are therefore comfortable to wear

- if you are not carrying out a measurement, the display can simply be folded up

Intuitive

- Intuitive operation through automatic tracking of your hands

- Interact with virtual objects, like with physical objects

- Voice recognition

Independent

- The HoloLens 2 can be compared to a computer. It is therefore not bound to additional hardware and can be used independently

- Unlimited freedom of movement through wireless operation

Engineering Services

We offer a variety of acoustic measurements by using our own equipment.

HoloMetrix News

Don’t miss out on news about innovative products, exclusive offers and useful services.

FAQ

Honoured with the German Innovation Award in “Gold”

The company excelled in the “Excellence in Business to Business” competition class in the “Machines & Engineering” category with the “HoloMetrix –Sound HUB”, a positioning aid that significantly simplifies acoustic measurements using augmented reality. In AR glasses, a virtual experimental set-up is presented three-dimensionally in the real environment. This approach eliminates the time-consuming and tedious manual determination of the measuring positions.

This is a significant step forward from the usual procedures offering an impressive demonstration of what measurement will look like in the future,” according to the jury’s statement.

Read the full article here.