Machine acoustics

Our services

- Determination of the actual acoustic condition of your machine

by the metrological determination of relevant emissions

like e.g. the sound power - Comparative measurement (benchmarking) for the acoustic optimization of products in the development phase

- Identification of the causes of unwanted noise by localization of the dominant sound sources

- Derivation of technical and economically reasonable measures for noise reduction

- Determination of transmission paths

- Frequency and third-octave band analyses

Brief overview

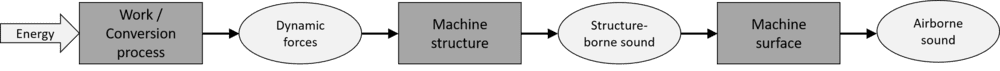

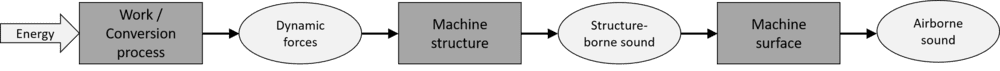

Due to conversion processes, energy of machines is converted into dynamic forces which cause the machine structure to vibrate. These vibrations (structure-borne sound) are transmitted into the air via the machine surface and are converted into airborne sound. If this airborne vibration is sufficiently large, we perceive it as noise. In the case of a very high intensity, this can even be a noise that is harmful to human hearing.

Additionally, large vibrations can damage the machine structure in the long run. Therefore, it is necessary to identify the causes of unwanted noise by sound measurements and to derive measures for its reduction. We are happy to support you in this process.

Generation and elimination of unwanted noise

The field of machine acoustics deals with the noises caused by machines. If these noises increase in volume, unpleasant loudness results. The focus is therefore often on reducing or changing them. To get an understanding of the possibilities of change, it is first important to understand the starting point. Therefore, the origin of one of these noises is explained in more detail in the following section.

Origin:

First of all, a working process is required which converts the energy. This is often a conversion of electrical energy into dynamic forces or torques. This is the case, for example, with an electric motor in a cutting machine. Multiple conversions can also occur within a machine. The electric motor drives the tool, but the interaction between the tool and the workpiece also generates forces (cutting forces). For this reason, various location-dependent dynamic forces act inside the machine structure. It can therefore be stated that the dynamic behavior inside the machine is superimposed with working forces.

Effect:

The internal dynamic forces cause the surface of the machine to vibrate as well. As soon as this occurs, the vibration is also transmitted to the air surrounding the machine. In concrete terms, this means that the air is pressed and compressed, which in turn can lead to a dynamic air pressure fluctuation that propagates through the room. If this air pressure fluctuation is sufficiently large and at the audible frequency, we perceive it as a sound. The intensity and the sound of the noise are in turn directly related to the amplitude and the frequency of the air pressure fluctuation. The following figure graphically illustrates the described generation mechanism.

Remedy:

Along this acoustic chain of origin, machine acoustics pursues the approach of eliminating the noise as early as possible. Ideally, this should be done in such a way that the disturbing noise does not occur in the first place.

However, it can happen that no reasonable or economical solution can be found for a machine that eliminates the source of a noise. In such cases, passive elements are used to reduce or absorb the noise that has been generated. A typical example of this is the noise barrier in road traffic.

In which phases are machine acoustic analyses used?

Machine acoustic analyses are used in the most diverse phases of the product life cycle of machines. HoloMetrix GmbH offers you its experience and services for noise reduction in every phase. We are happy to support you in any of these phases:

Development:

At this stage, it may be of interest to record the actual acoustic condition. Acoustic measurements are used for this purpose. Typical questions in this context are: Is the target being achieved? Are further acoustic measures necessary? Such measurements can be supplemented by so-called benchmarking (comparative measurements). Furthermore, identification measurements also play a decisive role in detecting acoustic problem areas.

Production:

At the production stage, acoustic measurements are often used for quality assurance. This requires a precisely defined measurement procedure so that the results remain comparable and „controllable“ at any given time. By means of an update measurement, the acoustic results obtained can flow into the development, especially into the calculation departments. This serves to make future predictions even more accurate.

Application phase:

Particularly in the case of larger stationary systems, which may also represent a larger investment, the acoustic properties should not change significantly over the operating period. Supplementary measurements and their comparison with previous measurement results are therefore also useful here. Furthermore, acoustic measurements and their subsequent FFT analysis can be used to identify and eliminate potential weak points at an early stage.

The field of machine acoustics is very comprehensive and versatile. We would be delighted to offer you specific advice for your project.

MACHINE ACOUSTICS

Our services

- Determination of the actual acoustic condition of your machine

by the metrological determination of relevant emissions

like e.g. the sound power - Comparative measurement (benchmarking) for the acoustic optimization of products in the development phase

- Identification of the causes of unwanted noise by localization of the dominant sound sources

- Derivation of technical and economically reasonable measures for noise reduction

- Determination of transmission paths

- Frequency and third-octave band analyses

Brief overview

Due to conversion processes, energy of machines is converted into dynamic forces which cause the machine structure to vibrate. These vibrations (structure-borne sound) are transmitted into the air via the machine surface and are converted into airborne sound. If this airborne vibration is sufficiently large, we perceive it as noise. In the case of a very high intensity, this can even be a noise that is harmful to human hearing.

Additionally, large vibrations can damage the machine structure in the long run. Therefore, it is necessary to identify the causes of unwanted noise by sound measurements and to derive measures for its reduction. We are happy to support you in this process.

Generation and elimination of unwanted noise

Origin:

First of all, a working process is required which converts the energy. This is often a conversion of electrical energy into dynamic forces or torques. This is the case, for example, with an electric motor in a cutting machine. Multiple conversions can also occur within a machine. The electric motor drives the tool, but the interaction between the tool and the workpiece also generates forces (cutting forces). For this reason, various location-dependent dynamic forces act inside the machine structure. It can therefore be stated that the dynamic behavior inside the machine is superimposed with working forces.Effect:

The internal dynamic forces cause the surface of the machine to vibrate as well. As soon as this occurs, the vibration is also transmitted to the air surrounding the machine. In concrete terms, this means that the air is pressed and compressed, which in turn can lead to a dynamic air pressure fluctuation that propagates through the room. If this air pressure fluctuation is sufficiently large and at the audible frequency, we perceive it as a sound. The intensity and the sound of the noise are in turn directly related to the amplitude and the frequency of the air pressure fluctuation. The following figure graphically illustrates the described generation mechanism.

Remedy:

In which phases are machine acoustic analyses used?

Development:

At this stage, it may be of interest to record the actual acoustic condition. Acoustic measurements are used for this purpose. Typical questions in this context are: Is the target being achieved? Are further acoustic measures necessary? Such measurements can be supplemented by so-called benchmarking (comparative measurements). Furthermore, identification measurements also play a decisive role in detecting acoustic problem areas.Production:

At the production stage, acoustic measurements are often used for quality assurance. This requires a precisely defined measurement procedure so that the results remain comparable and „controllable“ at any given time. By means of an update measurement, the acoustic results obtained can flow into the development, especially into the calculation departments. This serves to make future predictions even more accurate.Application phase:

Particularly in the case of larger stationary systems, which may also represent a larger investment, the acoustic properties should not change significantly over the operating period. Supplementary measurements and their comparison with previous measurement results are therefore also useful here. Furthermore, acoustic measurements and their subsequent FFT analysis can be used to identify and eliminate potential weak points at an early stage. The field of machine acoustics is very comprehensive and versatile. We would be delighted to offer you specific advice for your project.MACHINE ACOUSTICS

Our services

- Determination of the actual acoustic condition of your machine

by the metrological determination of relevant emissions

like e.g. the sound power - Comparative measurement (benchmarking) for the acoustic optimization of products in the development phase

- Identification of the causes of unwanted noise by localization of the dominant sound sources

- Derivation of technical and economically reasonable measures for noise reduction

- Determination of transmission paths

- Frequency and third-octave band analyses

Brief Overview

Due to conversion processes, energy of machines is converted into dynamic forces which cause the machine structure to vibrate. These vibrations (structure-borne sound) are transmitted into the air via the machine surface and are converted into airborne sound. If this airborne vibration is sufficiently large, we perceive it as noise. In the case of a very high intensity, this can even be a noise that is harmful to human hearing.

Additionally, large vibrations can damage the machine structure in the long run. Therefore, it is necessary to identify the causes of unwanted noise by sound measurements and to derive measures for its reduction. We are happy to support you in this process.

Generation and elimination of unwanted noise

The field of machine acoustics deals with the noises caused by machines. If these noises increase in volume, unpleasant loudness results. The focus is therefore often on reducing or changing them. To get an understanding of the possibilities of change, it is first important to understand the starting point. Therefore, the origin of one of these noises is explained in more detail in the following section.

Origin:

First of all, a working process is required which converts the energy. This is often a conversion of electrical energy into dynamic forces or torques. This is the case, for example, with an electric motor in a cutting machine. Multiple conversions can also occur within a machine. The electric motor drives the tool, but the interaction between the tool and the workpiece also generates forces (cutting forces). For this reason, various location-dependent dynamic forces act inside the machine structure. It can therefore be stated that the dynamic behavior inside the machine is superimposed with working forces.

Effect:

The internal dynamic forces cause the surface of the machine to vibrate as well. As soon as this occurs, the vibration is also transmitted to the air surrounding the machine. In concrete terms, this means that the air is pressed and compressed, which in turn can lead to a dynamic air pressure fluctuation that propagates through the room. If this air pressure fluctuation is sufficiently large and at the audible frequency, we perceive it as a sound. The intensity and the sound of the noise are in turn directly related to the amplitude and the frequency of the air pressure fluctuation. The following figure graphically illustrates the described generation mechanism.

![]()

Remedy:

Along this acoustic chain of origin, machine acoustics pursues the approach of eliminating the noise as early as possible. Ideally, this should be done in such a way that the disturbing noise does not occur in the first place.

However, it can happen that no reasonable or economical solution can be found for a machine that eliminates the source of a noise. In such cases, passive elements are used to reduce or absorb the noise that has been generated. A typical example of this is the noise barrier in road traffic.

In which phases are machine acoustic analyses used?

Machine acoustic analyses are used in the most diverse phases of the product life cycle of machines. HoloMetrix GmbH offers you its experience and services for noise reduction in every phase. We are happy to support you in any of these phases:

Development:

At this stage, it may be of interest to record the actual acoustic condition. Acoustic measurements are used for this purpose. Typical questions in this context are: Is the target being achieved? Are further acoustic measures necessary? Such measurements can be supplemented by so-called benchmarking (comparative measurements). Furthermore, identification measurements also play a decisive role in detecting acoustic problem areas.

Production:

At the production stage, acoustic measurements are often used for quality assurance. This requires a precisely defined measurement procedure so that the results remain comparable and „controllable“ at any given time. By means of an update measurement, the acoustic results obtained can flow into the development, especially into the calculation departments. This serves to make future predictions even more accurate.

Application phase:

Particularly in the case of larger stationary systems, which may also represent a larger investment, the acoustic properties should not change significantly over the operating period. Supplementary measurements and their comparison with previous measurement results are therefore also useful here. Furthermore, acoustic measurements and their subsequent FFT analysis can be used to identify and eliminate potential weak points at an early stage.

The field of machine acoustics is very comprehensive and versatile. We would be delighted to offer you specific advice for your project.